Welcome to our comprehensive guide on the 1995 Ford F350 Headlight Switch Wiring Diagram. Understanding the wiring diagram for your vehicle is crucial for proper maintenance and troubleshooting. In this article, we will cover the importance of these diagrams, how to interpret them effectively, and how they can be used for troubleshooting electrical problems.

Why are 1995 Ford F350 Headlight Switch Wiring Diagrams Essential?

Wiring diagrams are essential for any vehicle as they provide a visual representation of the electrical system. Here are a few reasons why the 1995 Ford F350 Headlight Switch Wiring Diagram is crucial:

- Helps in understanding the layout of the electrical system

- Aids in identifying connections and components

- Assists in diagnosing and repairing electrical issues

How to Read and Interpret 1995 Ford F350 Headlight Switch Wiring Diagrams Effectively

Reading and interpreting wiring diagrams can be daunting for some, but with a few tips, you can easily decipher the information presented. Here’s how you can effectively read and interpret the 1995 Ford F350 Headlight Switch Wiring Diagram:

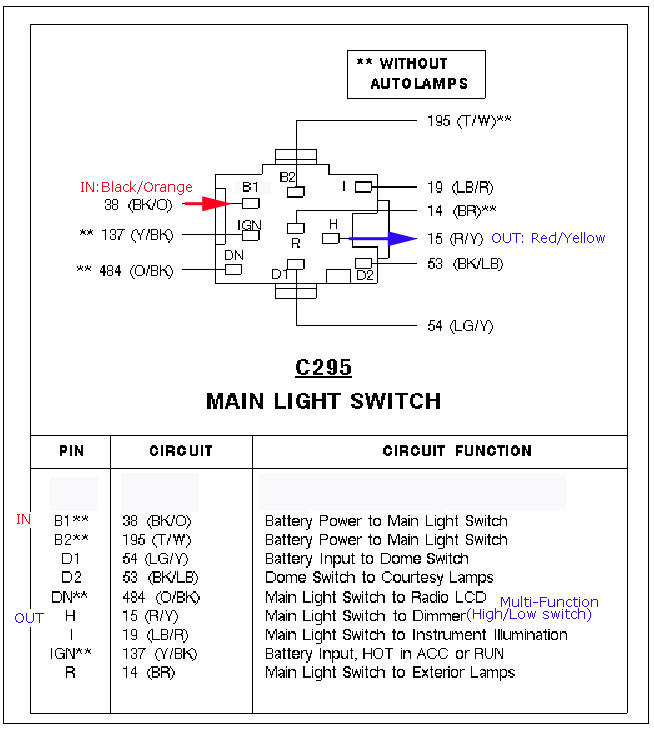

- Start by identifying the components and their symbols

- Follow the flow of the electrical current

- Pay attention to the color codes and labels

Using 1995 Ford F350 Headlight Switch Wiring Diagrams for Troubleshooting Electrical Problems

Wiring diagrams are invaluable when it comes to troubleshooting electrical problems in your vehicle. By following the wiring diagram, you can pinpoint the exact location of the issue and make necessary repairs. Here’s how you can use the 1995 Ford F350 Headlight Switch Wiring Diagram for troubleshooting:

- Trace the wiring to identify any loose connections or damaged wires

- Check for continuity using a multimeter

- Refer to the wiring diagram to locate fuses and relays that may be causing the problem

Importance of Safety When Working with Electrical Systems

When working with electrical systems and using wiring diagrams, it is crucial to prioritize safety. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on any electrical components

- Wear insulated gloves and eye protection to prevent any accidents

- Double-check your work before reconnecting the battery to avoid short circuits

1995 Ford F350 Headlight Switch Wiring Diagram

Ford Headlight Switch Wiring Schematics

Ford Headlight Switch Wiring

Headlight Switch Wiring Diagram F350

Ford F 350 Headlight Switch Wiring Diagram – Wiring Diagram

Ford Headlight Switch Diagram

Ford F-350 Super Duty FX4 Headlight Switch – Q&A on Symbols and Wiring