When it comes to working on a classic car like the 1966 Ford Mustang, having access to the right wiring diagrams is essential. In this article, we will explore the importance of the 1966 Ford Mustang Alternator Wiring Diagram and how they can be used to troubleshoot electrical problems effectively.

Why are 1966 Ford Mustang Alternator Wiring Diagram Essential?

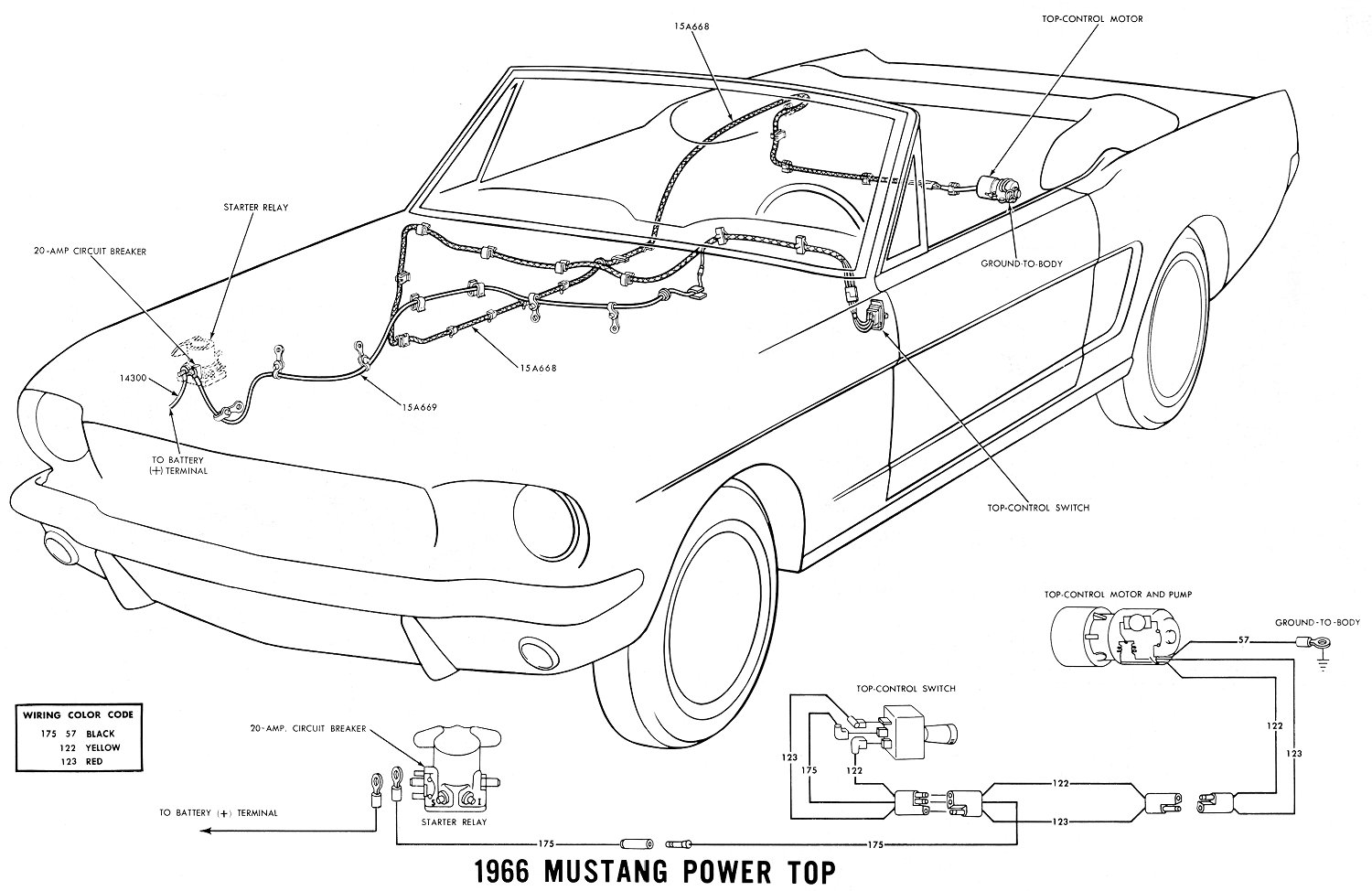

The wiring diagram for the alternator in a 1966 Ford Mustang is crucial for understanding how the electrical system is set up. Without this diagram, it can be challenging to diagnose and repair any issues that may arise with the alternator or related components. Here are a few reasons why these wiring diagrams are essential:

- Helps identify the different wires and their functions

- Assists in locating components within the electrical system

- Guides in understanding the circuit connections and how they are wired

How to Read and Interpret 1966 Ford Mustang Alternator Wiring Diagram Effectively

Reading and interpreting a wiring diagram may seem daunting at first, but with some guidance, it can be a valuable tool in troubleshooting electrical issues. Here are some tips on how to read and interpret the 1966 Ford Mustang Alternator Wiring Diagram effectively:

- Start by identifying the components and their symbols on the diagram

- Follow the wiring paths to understand how the circuit is connected

- Pay attention to color codes and labels for each wire

Using 1966 Ford Mustang Alternator Wiring Diagram for Troubleshooting

When faced with electrical problems in your 1966 Ford Mustang, the wiring diagram for the alternator can be a lifesaver. Here’s how you can use these diagrams for troubleshooting:

- Check for continuity in the wiring to ensure there are no breaks or loose connections

- Identify any fuses or relays that may be causing the issue

- Refer to the diagram to understand the flow of electricity and pinpoint the source of the problem

Importance of Safety When Working with Electrical Systems

Working with electrical systems can be dangerous if proper precautions are not taken. Here are some safety tips and best practices to keep in mind:

- Always disconnect the battery before working on any electrical components

- Use insulated tools to avoid the risk of electric shock

- Avoid working on wet surfaces or in damp conditions to prevent electrical hazards

1966 Ford Mustang Alternator Wiring Diagram

1966 Mustang Alternator Wiring Diagram

1966 Mustang Alternator Wiring Diagram – Wiring Diagram

66 Mustang Alternator Wiring Diagram

Step-by-Step Guide to 1966 Mustang Alternator Wiring: A Must-Know for

1966 Mustang Alternator Wiring

1966 Mustang Alternator Wiring Diagram – Wiring Diagram